A unique 400 VoltDC Distributed Servo Drive system for industrial applications

According to MarketsandMarkets.com, the servo motor and drive market is expected to reach USD 15.92 Billion by 2022, at a CAGR of 6.25% between 2016 and 2022.The rapid growth in automation as well as the international adoption of more stringent energy-efficiency standards are some of the reasons behind the significant growth in the servo motor and drive markets.

Distributed 400 VoltDC servo drive systems using normal 3 core cable without shielding

SiGaN launches a breakthrough full integrated Servo Drive

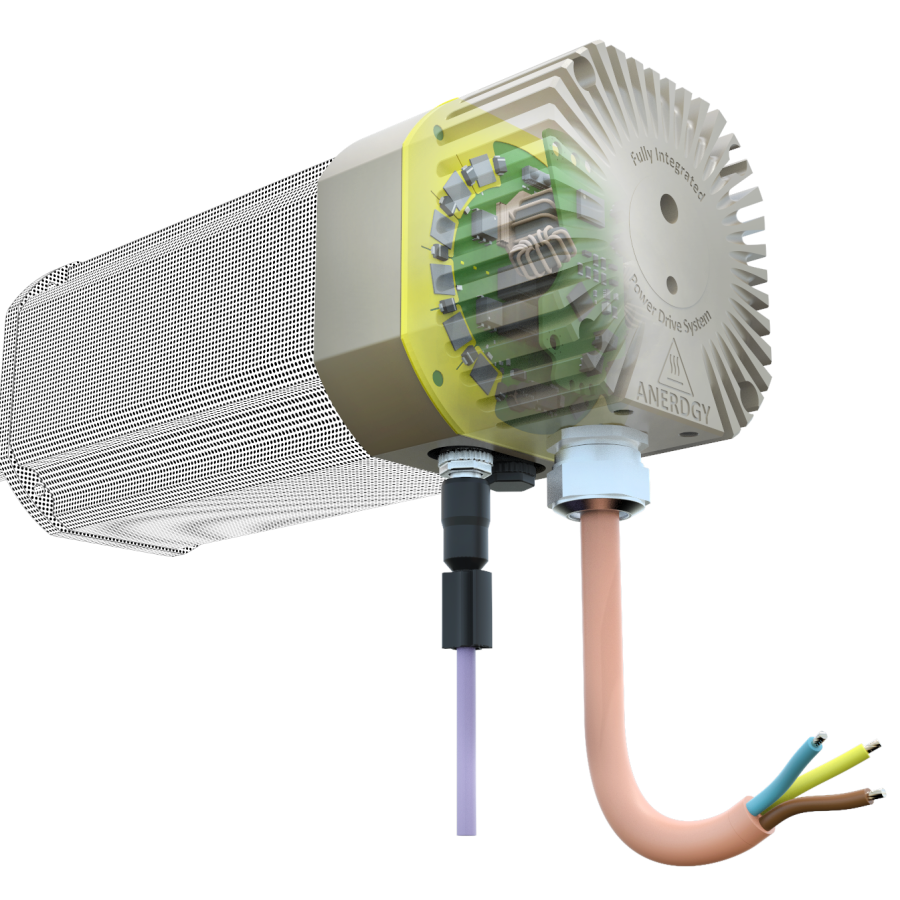

The new AFi-Drive distributed Servo Drive system breaks new ground for modular machine concepts. The space-saving AFi-Drive integrates a servo drive directly into a servomotor in an ultra-compact design. By relocating the power electronics directly into the machine, the control cabinet only needs to house a simple wiring junction box to supply power to multiple servo drives. Contrary to other solutions, it also only requires normal 3 core cable without shielding. The result: significant savings in terms of cost, space, materials and installation effort.

More information about using the AFi module drive in domestic elevators.

Taking servo drive integration to 400 VoltDC applications

Many integrated servo drives already exist for Extra Low Voltage systems, however with the very latest in semi-conductor technologies, we have been able to jump the hurdles of packaging a 400V DC drive into the necessary frame size, using passive cooling as well as achieving EMC compliance without shielded cables. The benefits of this are numerous, including reduced cable cross sectional areas, no expensive Switch Mode Power Supplies requiring clean, dry cooling air and a passive more robust AC to DC stage. All of these result in higher reliability, simplified installation and importantly achieve cost reductions.

Peter Shaw, CEO and co-founder

We have developed a great proprietary solution for our renewable energy application. We see increased interest from other markets with harsh environments such as building automation and industrial machinery where both energy efficiency and distributed system are needed.

Sven Koehler, CEO and co-founder.

SiGaN is taking its technology to address new and promising markets.

The AC servo motors are expected to hold the largest share in the servo motor and drive market. The high capability and dynamic functionality of AC servo motors is the major reason behind its increasing use in various industries such as automotive, food processing and packaging among others.

With this new solution, SiGaN integrates Motor control, Sensors, External communication, Programmable logic controller (PLC), brake resistor as well as an AC Input or DC Input/ Output power stage. Therefore, all application requirements can be addressed in a decentralised and modular way. AFi-Drive customers value particularly the possibility to use normal 3 core cable without shielding, the IP65 to IP69k as well as flexible Communication – CAN, EtherCAT, …

SiGaN is also able to offer its clients the ability to continue to work with their preferred motor suppliers. This is done by integrating the relevant OEM components with its unique control unit.

With this first product, Anerdgy addresses the growing need for Distributed Servo Drive systems for industrial applications, combining simpler installation and lower cost maintenance for a reduced overall Total Cost of Ownership.